Radial buckling process for joints

Radial buckling process for joints

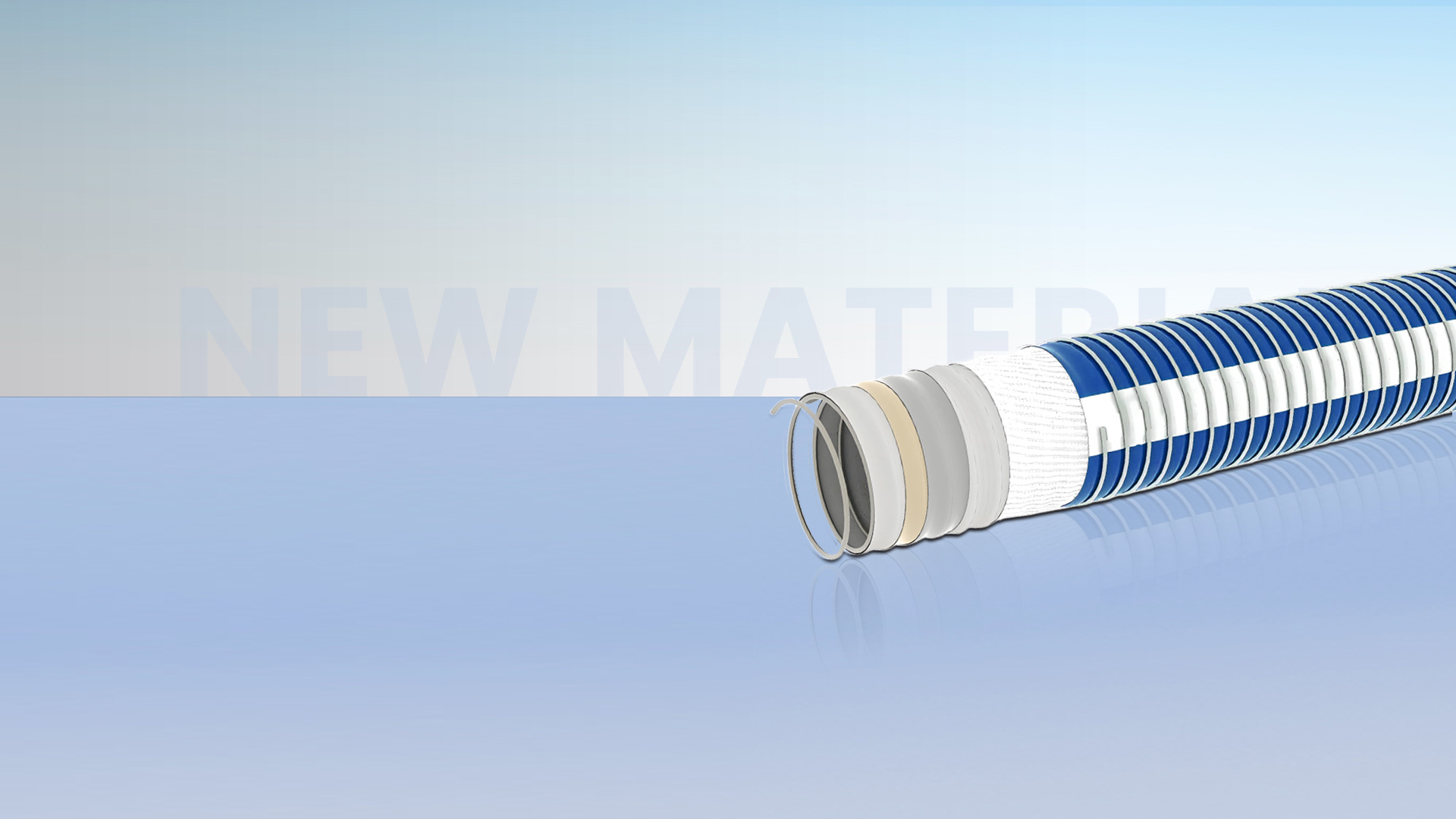

MATEC composite hose fitting process

When assembling and connecting the composite hose and the joint, first rotate the hose into the spiral ring cavity of the joint sheath filled with sealant, and then use a special hydraulic device to circumferentially squeeze and contract the outer ring of the joint sheath to ensure that the hose is safely fastened inside the joint sheath. This double-sealing process ensures that the composite hose can be safely used in extremely harsh working conditions such as ship-to-ship medium transportation, avoiding major accidents such as hose and joint detachment causing environmental pollution.