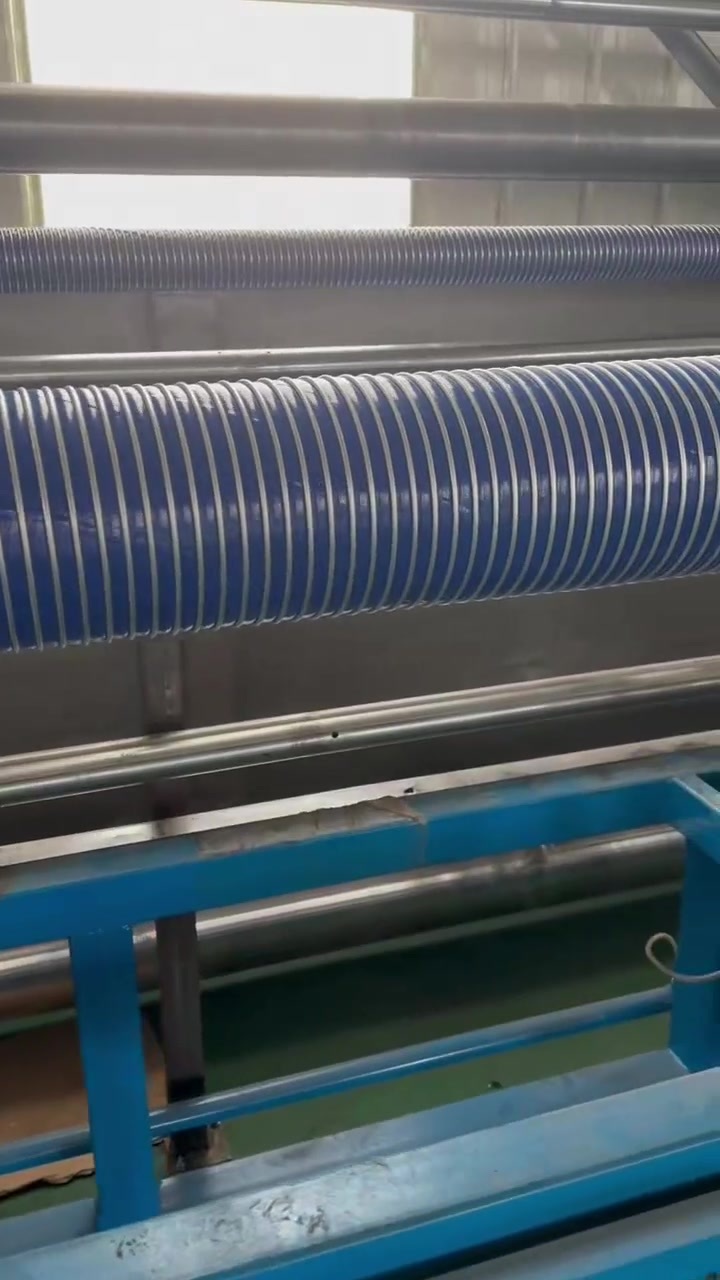

Food-grade composite hoses for grain and oil

Food-grade composite hoses for grain and oil

It can be conveyed under positive and negative pressure conditionsPeanut oil, olive oil, palm oil and various other edible grains and oils.The raw materials of food hygiene standards and the special manufacturing process ensure the safety and hygiene of the medium conveyed by the hose.

Keyword:

Food-grade composite hoses for grain and oil

Category:

Discription

The composite hose independently developed by Tianhua New Material Technology Co., Ltd. is a new generation of fluid transportation solution that combines light weight, high strength and multi-functionality. Through the innovative design of multi-layer composite materials, the product breaks through the technical limitations of traditional metal and rubber hoses, and is widely used in petrochemical, shipping, food and medicine, agricultural irrigation and industrial manufacturing, redefining the safety standard of fluid transmission with excellent performance.

The composite hose adopts the precision stacking process of “functional layer + reinforcement layer + protection layer” to realize the comprehensive optimization of performance:

lining layer:PTFE, food-grade polyurethane and other special materials, resistant to strong acids, alkalis, oils and solvents, to ensure that the medium is pure and free of pollution.

Reinforcement layer:high-tension synthetic fiber and stainless steel wire spiral winding, giving the hose ultra-high pressure-bearing capacity (up to 4.0MPa), anti-negative pressure performance increased by 60%.

Cover:UV-modified TPU material, with wear-resistant, anti-static, weather-resistant characteristics, adaptable to -20 ℃ to +120 ℃ extreme working conditions.

Specification parameters

Tube structure and materials

| Structure name | Materials |

| Inner steel ring | SS316 stainless steel wire |

| Inner surface layer | Polyurethane lining I |

| Pipe body reinforcing layer | PVC coated polyester |

| Coat | S316 stainless steel wire |

| Outer steel ring |

Technical parameters

| Maximum stretching amount | 10%(under experimental pressure) |

| Resistance | <10 Ohm p/lgt |

| Maximum distortion degree | 10°p/m |

| Vacuum degree | 0.9bar |

| Minimum burst pressure | Five times the allowable working pressure |

| Design temperature | -30℃ to+100℃ |

| Identify colors | Light blue |

Product series

P/N | Duty | N.D. | max.w.p. | Bending radius | Weight | Max.length | ||||

|

| Inch | mm | Psi | bar | Inches | mm | Kg/m | Inches | m |

Pxxxx7001253107 Pxxxx7001263107 | Light load | 1 | 28 | 100 | 7 | 4.9 | 125 | 0.85 | 65 | 20 |

1-¹/2 | 40 | 100 | 7 | 5.9 | 150 | 1.15 | 100 | 30 | ||

2 | 50 | 100 | 7 | 7.9 | 200 | 1.3 | 100 | 30 | ||

2-¹/2 | 65 | 100 | 7 | 8.3 | 210 | 2.2 | 100 | 30 | ||

3 | 80 | 100 | 7 | 11.8 | 300 | 2.7 | 100 | 30 | ||

4 | 100 | 100 | 7 | 15.7 | 400 | 4.4 | 100 | 30 | ||

Pxxxx7001253110 Pxxxx7001263110 | Standard | 1 | 28 | 150 | 10.5 | 4.9 | 125 | 0.95 | 65 | 20 |

1-¹/2 | 40 | 150 | 10.5 | 5.9 | 150 | 1.7 | 100 | 30 | ||

2 | 50 | 150 | 10.5 | 7.9 | 200 | 1.8 | 100 | 30 | ||

2-¹/2 | 65 | 150 | 10.5 | 8.3 | 210 | 2.9 | 100 | 30 | ||

3 | 80 | 150 | 10.5 | 11.8 | 300 | 3.5 | 100 | 30 | ||

4 | 100 | 150 | 10.5 | 15.7 | 400 | 5.5 | 100 | 30 | ||

Pxxxx7001253114 Pxxxx7001263114 | Heavy load | 3 | 80 | 200 | 14 | 13.8 | 350 | 4.5 | 100 | 30 |

4 | 100 | 200 | 14 | 15.7 | 400 | 7.9 | 100 | 30 | ||

5 | 125 | 200 | 14 | 20.1 | 510 | 9.7 | 100 | 30 | ||

6 | 150 | 200 | 14 | 22.6 | 575 | 12.4 | 100 | 30 | ||

8 | 200 | 200 | 14 | 31.5 | 800 | 21.8 | 100 | 30 | ||

10 | 250 | 200 | 14 | 39.37 | 1000 | 26.7 | 65 | 20 | ||

12 | 300 | 200 | 14 | 47.24 | 1200 | 32 | 59 | 18 | ||

Related Video

Product Video19

Product Video17

Product Video14

Product Video12

Industry Application

-

Energy & Chemicals

Crude oil transportation, tanker loading and unloading on land/sea platforms

Transmission of acidic and alkaline chemical media, eliminating the risk of galvanic corrosion of metal pipelines -

Shipping

Fuel filling and ballast water transfer for ships

Equipped with anti-static certification to meet IMO International Maritime Safety Code. -

Food & Pharmaceutical

FDA certified material, meets GMP cleanliness standard

Liquid raw materials, CIP cleaning system dedicated pipeline -

Industry

Hydraulic system, compressed air transportation

Replacement of rigid piping, solving the problem of complex space piping

Six Core Advantages

Lightweight and portable

Weight is only 1/5 of the same specification metal pipe, reducing the intensity of manual operation and logistics costs

Flexible and anti-flexing

Minimum bending radius up to 4 times the diameter of the pipe, increasing the adaptability of the installation by 80%

Zero Maintenance Costs

No corrosion and delamination, service life of more than 10 years

Safe and Explosion-proof

Multilayered anti-static design, eliminating the risk of working in a flammable environment

Environmental Protection and Energy Saving

The whole process of no-leakage design, reducing the loss of medium and environmental pollution

Customized service

Support for rapid customization of caliber (1"-12"), length, and connector form.

Qualification

Tianhua New Material Technology Co., Ltd. has been certified by UDEM, and its products comply with UDEM and other international authoritative standards. Equipped with a full-process quality tracking system, from raw material testing to finished product burst testing, to ensure that every meter of hose meets the requirements of industrial-grade reliability.

Choosing Tianhua composite

hoseis not only choosing a product,

but also choosing the

7×24 hours professional technical support

Worldwide 1-year long warranty

Industry-leading total fluid transfer solutions

Realted Product

Consult

You can send it to us by filling out the form, or you can contact us on WeChat!

* Contact us today for exclusive selection programs and technical brochures!